Embark on a journey to discover the most effective ways to control fleet maintenance costs through the integration of technology. This guide will delve into the strategies and tools that can revolutionize how businesses manage their fleet maintenance expenses.

Introduction to Fleet Maintenance Costs

Fleet maintenance costs refer to the expenses associated with keeping a fleet of vehicles operational and in good condition. These costs can include regular servicing, repairs, parts replacement, and other maintenance-related expenses. Managing fleet maintenance costs efficiently is crucial for businesses that rely on a fleet of vehicles to conduct their operations.

By optimizing maintenance expenses, companies can improve their bottom line, ensure the safety and reliability of their vehicles, and minimize downtime that can impact productivity. Technology plays a key role in helping businesses streamline and optimize their fleet maintenance processes, ultimately reducing costs and improving overall efficiency.

Importance of Managing Fleet Maintenance Costs

- Proper management of fleet maintenance costs can lead to significant cost savings for businesses in the long run.

- Efficient maintenance practices can help prevent costly breakdowns and repairs, reducing unexpected expenses.

- Regular maintenance can extend the lifespan of vehicles, delaying the need for costly replacements.

Technology for Optimizing Fleet Maintenance Expenses

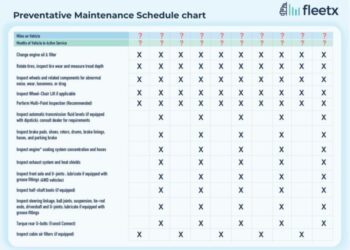

- Vehicle tracking systems can help monitor the usage and performance of each vehicle in the fleet, allowing for proactive maintenance scheduling.

- Diagnostic tools and software can aid in identifying potential issues early on, preventing major breakdowns and reducing repair costs.

- Automated maintenance scheduling systems can ensure that vehicles receive timely servicing, reducing the risk of costly delays or oversights.

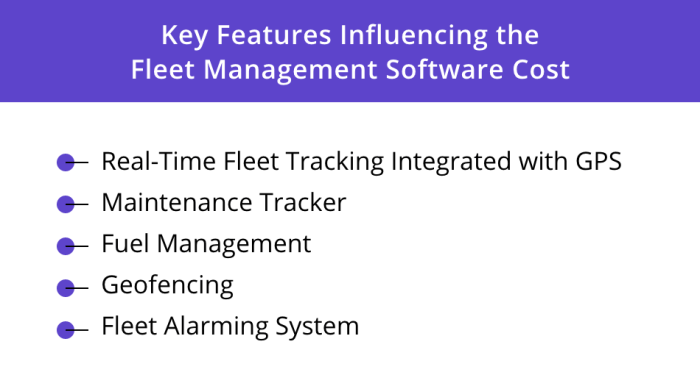

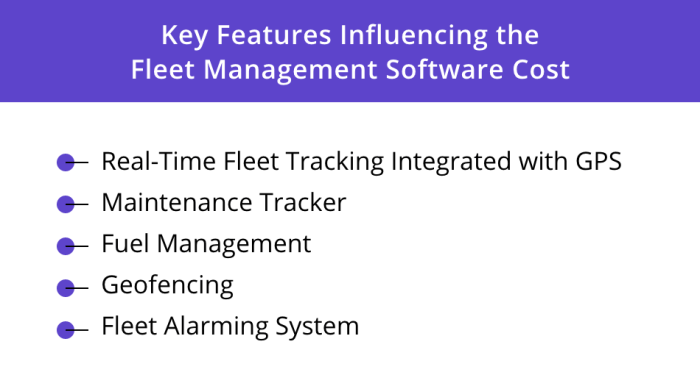

Utilizing Fleet Management Software

Fleet management software plays a crucial role in tracking maintenance schedules and costs for a fleet of vehicles. By utilizing this technology, companies can effectively manage their maintenance tasks and expenses in a streamlined manner.

Tracking Maintenance Schedules and Costs

- Fleet management software allows companies to schedule regular maintenance tasks for each vehicle in the fleet, ensuring that all necessary services are completed on time.

- The software also tracks the costs associated with each maintenance activity, providing a detailed overview of the expenses incurred for keeping the vehicles in optimal condition.

- By having access to this data, companies can better plan and budget for future maintenance needs, preventing unexpected costs and breakdowns.

Benefits of Analyzing Data for Cost-Saving Opportunities

- Fleet management software enables companies to analyze maintenance data to identify trends and patterns that can help in reducing costs.

- By identifying areas where maintenance expenses are high or unnecessary, companies can implement strategies to optimize their maintenance processes and save money.

- The ability to generate reports and dashboards from the software allows for a clear visualization of cost-saving opportunities, making it easier for companies to make informed decisions.

Real-Life Examples of Success

- XYZ Company implemented fleet management software and was able to reduce their maintenance costs by 15% within the first year of use.

- ABC Logistics saw a significant decrease in breakdowns and emergency repairs after adopting fleet management software, resulting in a 20% decrease in maintenance expenses.

- DEF Transportation used the data analysis features of the software to identify inefficiencies in their maintenance processes, leading to a 10% cost savings in the long run.

Implementing Predictive Maintenance Technologies

Predictive maintenance in fleet management involves using data and technology to predict when maintenance is needed on vehicles before a breakdown occurs. This proactive approach helps to prevent costly repairs and downtime by addressing issues before they escalate.

Benefits of Predictive Maintenance Technologies

- Predictive maintenance tools analyze data from vehicles to identify patterns and trends that indicate potential issues.

- By predicting maintenance needs in advance, fleet managers can schedule maintenance during non-peak hours, minimizing disruption to operations.

- Preventive maintenance can help extend the lifespan of vehicles and reduce overall maintenance costs over time.

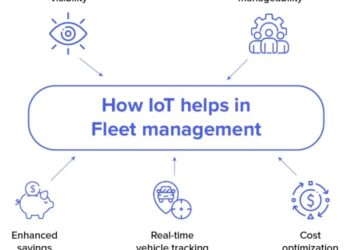

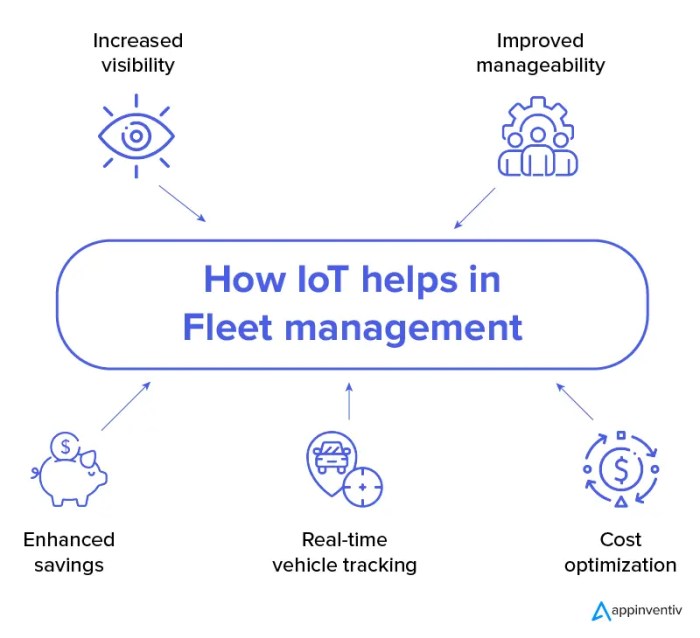

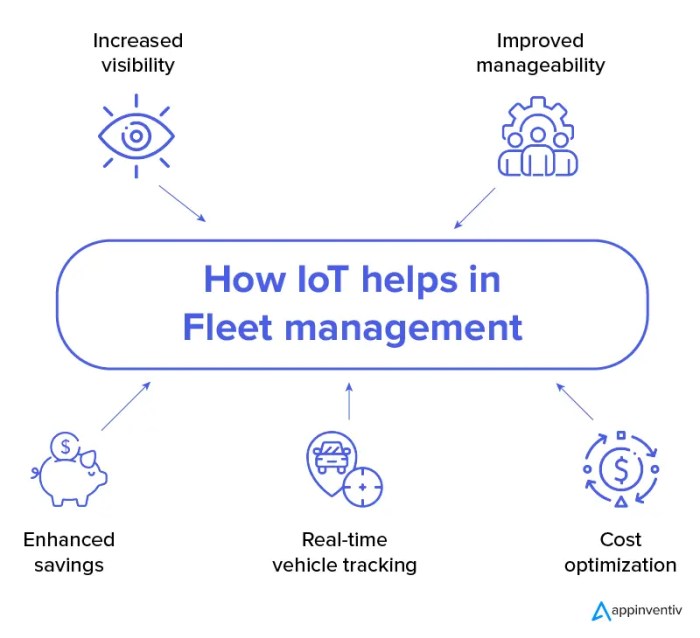

Leveraging Telematics for Cost-Efficient Maintenance

Telematics plays a crucial role in modern fleet management by providing real-time data on vehicle health and performance. This data can be leveraged to optimize maintenance schedules and reduce operational costs significantly

Monitoring Vehicle Health and Performance

Telematics systems utilize onboard sensors to collect data on various aspects of a vehicle's performance, such as engine health, fuel consumption, and driving patterns. By monitoring this data in real-time, fleet managers can proactively identify maintenance issues before they escalate, preventing costly breakdowns and repairs.

- Telematics data can alert fleet managers to potential maintenance issues, allowing for timely intervention and preventive maintenance.

- By tracking fuel consumption and engine performance, telematics can help optimize vehicle efficiency, reducing fuel costs and extending the lifespan of the fleet.

Optimizing Maintenance Schedules

Telematics data provides valuable insights into each vehicle's usage patterns, allowing fleet managers to create customized maintenance schedules based on actual wear and tear. By implementing predictive maintenance strategies, fleets can avoid unnecessary servicing and reduce downtime, ultimately saving on maintenance costs.

- Telematics data can be used to schedule maintenance tasks based on actual vehicle usage, optimizing downtime and reducing overall maintenance expenses.

- By analyzing historical data on repairs and maintenance, fleet managers can identify trends and patterns to optimize maintenance schedules further.

Integrating Telematics with Maintenance Operations

Integrating telematics data with maintenance operations can streamline the entire maintenance process, from scheduling to execution. By automating maintenance alerts and work orders based on real-time data, fleets can improve efficiency, reduce administrative overhead, and ensure timely servicing.

- Telematics integration with maintenance software allows for automatic generation of work orders based on vehicle diagnostics, eliminating manual intervention and reducing human error.

- By combining telematics data with predictive maintenance technologies, fleets can implement a proactive maintenance approach, reducing costs associated with reactive repairs.

Cost-Effective Parts Inventory Management

Efficient parts inventory management is crucial for reducing maintenance costs and ensuring smooth operations. By leveraging technology, businesses can optimize their inventory and streamline procurement processes to save time and money.

Strategies for Efficient Parts Inventory Management

Implementing the following strategies can help businesses effectively manage their parts inventory:

- Utilize inventory management software to track parts usage, reorder points, and stock levels in real-time.

- Implement barcode scanning or RFID technology for accurate inventory tracking and reduced manual errors.

- Establish vendor relationships to ensure timely delivery of parts and negotiate pricing for bulk orders.

- Create a standardized inventory management process to streamline operations and reduce inefficiencies.

Importance of Inventory Optimization

Optimizing inventory is essential for reducing carrying costs, minimizing stockouts, and preventing overstock situations. By maintaining the right balance of parts in stock, businesses can avoid unnecessary expenses and improve overall efficiency.

Tips for Streamlining Parts Procurement and Inventory Control

Here are some tips for leveraging technology to streamline parts procurement and inventory control processes:

- Automate parts ordering through inventory management software to reduce manual intervention and errors.

- Implement predictive analytics to forecast parts demand and optimize inventory levels accordingly.

- Utilize cloud-based inventory management systems for real-time access to inventory data from anywhere.

- Integrate parts suppliers into your inventory management system for seamless communication and order processing.

Final Conclusion

In conclusion, by leveraging technology and innovative solutions, businesses can significantly reduce their fleet maintenance costs, leading to improved efficiency and profitability. Implementing these practices can pave the way for a more sustainable and cost-effective fleet management approach.

Q&A

How can predictive maintenance technologies help in reducing fleet maintenance costs?

Predictive maintenance tools can anticipate potential issues before they escalate, allowing for proactive maintenance and avoiding costly breakdowns.

What role does telematics play in optimizing maintenance schedules?

Telematics provides real-time data on vehicle health and performance, enabling businesses to schedule maintenance tasks more efficiently and reduce overall costs.

Why is efficient parts inventory management crucial for reducing maintenance expenses?

Optimizing parts inventory ensures that necessary components are available when needed, minimizing downtime and avoiding unnecessary costs.

data-ad-client="ca-pub-1784768207398293" data-ad-slot="7141627725" data-ad-format="auto" data-full-width-responsive="true">Embark on a journey to discover the most effective ways to control fleet maintenance costs through the integration of technology. This guide will delve into the strategies and tools that can revolutionize how businesses manage their fleet maintenance expenses.

Introduction to Fleet Maintenance Costs

Fleet maintenance costs refer to the expenses associated with keeping a fleet of vehicles operational and in good condition. These costs can include regular servicing, repairs, parts replacement, and other maintenance-related expenses. Managing fleet maintenance costs efficiently is crucial for businesses that rely on a fleet of vehicles to conduct their operations.

By optimizing maintenance expenses, companies can improve their bottom line, ensure the safety and reliability of their vehicles, and minimize downtime that can impact productivity. Technology plays a key role in helping businesses streamline and optimize their fleet maintenance processes, ultimately reducing costs and improving overall efficiency.

Importance of Managing Fleet Maintenance Costs

- Proper management of fleet maintenance costs can lead to significant cost savings for businesses in the long run.

- Efficient maintenance practices can help prevent costly breakdowns and repairs, reducing unexpected expenses.

- Regular maintenance can extend the lifespan of vehicles, delaying the need for costly replacements.

Technology for Optimizing Fleet Maintenance Expenses

- Vehicle tracking systems can help monitor the usage and performance of each vehicle in the fleet, allowing for proactive maintenance scheduling.

- Diagnostic tools and software can aid in identifying potential issues early on, preventing major breakdowns and reducing repair costs.

- Automated maintenance scheduling systems can ensure that vehicles receive timely servicing, reducing the risk of costly delays or oversights.

Utilizing Fleet Management Software

Fleet management software plays a crucial role in tracking maintenance schedules and costs for a fleet of vehicles. By utilizing this technology, companies can effectively manage their maintenance tasks and expenses in a streamlined manner.

Tracking Maintenance Schedules and Costs

- Fleet management software allows companies to schedule regular maintenance tasks for each vehicle in the fleet, ensuring that all necessary services are completed on time.

- The software also tracks the costs associated with each maintenance activity, providing a detailed overview of the expenses incurred for keeping the vehicles in optimal condition.

- By having access to this data, companies can better plan and budget for future maintenance needs, preventing unexpected costs and breakdowns.

Benefits of Analyzing Data for Cost-Saving Opportunities

- Fleet management software enables companies to analyze maintenance data to identify trends and patterns that can help in reducing costs.

- By identifying areas where maintenance expenses are high or unnecessary, companies can implement strategies to optimize their maintenance processes and save money.

- The ability to generate reports and dashboards from the software allows for a clear visualization of cost-saving opportunities, making it easier for companies to make informed decisions.

Real-Life Examples of Success

- XYZ Company implemented fleet management software and was able to reduce their maintenance costs by 15% within the first year of use.

- ABC Logistics saw a significant decrease in breakdowns and emergency repairs after adopting fleet management software, resulting in a 20% decrease in maintenance expenses.

- DEF Transportation used the data analysis features of the software to identify inefficiencies in their maintenance processes, leading to a 10% cost savings in the long run.

Implementing Predictive Maintenance Technologies

Predictive maintenance in fleet management involves using data and technology to predict when maintenance is needed on vehicles before a breakdown occurs. This proactive approach helps to prevent costly repairs and downtime by addressing issues before they escalate.

Benefits of Predictive Maintenance Technologies

- Predictive maintenance tools analyze data from vehicles to identify patterns and trends that indicate potential issues.

- By predicting maintenance needs in advance, fleet managers can schedule maintenance during non-peak hours, minimizing disruption to operations.

- Preventive maintenance can help extend the lifespan of vehicles and reduce overall maintenance costs over time.

Leveraging Telematics for Cost-Efficient Maintenance

Telematics plays a crucial role in modern fleet management by providing real-time data on vehicle health and performance. This data can be leveraged to optimize maintenance schedules and reduce operational costs significantly

Monitoring Vehicle Health and Performance

Telematics systems utilize onboard sensors to collect data on various aspects of a vehicle's performance, such as engine health, fuel consumption, and driving patterns. By monitoring this data in real-time, fleet managers can proactively identify maintenance issues before they escalate, preventing costly breakdowns and repairs.

- Telematics data can alert fleet managers to potential maintenance issues, allowing for timely intervention and preventive maintenance.

- By tracking fuel consumption and engine performance, telematics can help optimize vehicle efficiency, reducing fuel costs and extending the lifespan of the fleet.

Optimizing Maintenance Schedules

Telematics data provides valuable insights into each vehicle's usage patterns, allowing fleet managers to create customized maintenance schedules based on actual wear and tear. By implementing predictive maintenance strategies, fleets can avoid unnecessary servicing and reduce downtime, ultimately saving on maintenance costs.

- Telematics data can be used to schedule maintenance tasks based on actual vehicle usage, optimizing downtime and reducing overall maintenance expenses.

- By analyzing historical data on repairs and maintenance, fleet managers can identify trends and patterns to optimize maintenance schedules further.

Integrating Telematics with Maintenance Operations

Integrating telematics data with maintenance operations can streamline the entire maintenance process, from scheduling to execution. By automating maintenance alerts and work orders based on real-time data, fleets can improve efficiency, reduce administrative overhead, and ensure timely servicing.

- Telematics integration with maintenance software allows for automatic generation of work orders based on vehicle diagnostics, eliminating manual intervention and reducing human error.

- By combining telematics data with predictive maintenance technologies, fleets can implement a proactive maintenance approach, reducing costs associated with reactive repairs.

Cost-Effective Parts Inventory Management

Efficient parts inventory management is crucial for reducing maintenance costs and ensuring smooth operations. By leveraging technology, businesses can optimize their inventory and streamline procurement processes to save time and money.

Strategies for Efficient Parts Inventory Management

Implementing the following strategies can help businesses effectively manage their parts inventory:

- Utilize inventory management software to track parts usage, reorder points, and stock levels in real-time.

- Implement barcode scanning or RFID technology for accurate inventory tracking and reduced manual errors.

- Establish vendor relationships to ensure timely delivery of parts and negotiate pricing for bulk orders.

- Create a standardized inventory management process to streamline operations and reduce inefficiencies.

Importance of Inventory Optimization

Optimizing inventory is essential for reducing carrying costs, minimizing stockouts, and preventing overstock situations. By maintaining the right balance of parts in stock, businesses can avoid unnecessary expenses and improve overall efficiency.

Tips for Streamlining Parts Procurement and Inventory Control

Here are some tips for leveraging technology to streamline parts procurement and inventory control processes:

- Automate parts ordering through inventory management software to reduce manual intervention and errors.

- Implement predictive analytics to forecast parts demand and optimize inventory levels accordingly.

- Utilize cloud-based inventory management systems for real-time access to inventory data from anywhere.

- Integrate parts suppliers into your inventory management system for seamless communication and order processing.

Final Conclusion

In conclusion, by leveraging technology and innovative solutions, businesses can significantly reduce their fleet maintenance costs, leading to improved efficiency and profitability. Implementing these practices can pave the way for a more sustainable and cost-effective fleet management approach.

Q&A

How can predictive maintenance technologies help in reducing fleet maintenance costs?

Predictive maintenance tools can anticipate potential issues before they escalate, allowing for proactive maintenance and avoiding costly breakdowns.

What role does telematics play in optimizing maintenance schedules?

Telematics provides real-time data on vehicle health and performance, enabling businesses to schedule maintenance tasks more efficiently and reduce overall costs.

Why is efficient parts inventory management crucial for reducing maintenance expenses?

Optimizing parts inventory ensures that necessary components are available when needed, minimizing downtime and avoiding unnecessary costs.

data-ad-client="ca-pub-1784768207398293" data-ad-slot="7141627725" data-ad-format="auto" data-full-width-responsive="true">