Fleet Maintenance KPIs Every Manager Should Track sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with casual formal language style and brimming with originality from the outset.

Exploring the importance of tracking KPIs in fleet maintenance is not only essential but also a strategic move for managers looking to optimize their operations. By delving into the world of essential Fleet Maintenance KPIs, this discussion aims to shed light on the crucial metrics that can drive efficiency and cost-effectiveness in fleet management.

Importance of Fleet Maintenance KPIs

Monitoring Key Performance Indicators (KPIs) in fleet maintenance is crucial for ensuring the smooth operation and longevity of a company's vehicles. By tracking specific metrics, managers can gain valuable insights into the health of their fleet and make informed decisions to optimize maintenance processes and reduce costs.

Enhanced Maintenance Planning

- Tracking KPIs such as vehicle downtime, maintenance costs, and preventive maintenance compliance allows managers to identify patterns and trends in maintenance needs.

- With this data, managers can create comprehensive maintenance schedules, anticipate potential issues, and proactively address maintenance requirements, minimizing unexpected breakdowns and disruptions.

Improved Resource Utilization

- Efficiently managing resources like labor, parts, and equipment is essential for maintaining a cost-effective fleet maintenance program.

- By monitoring KPIs related to inventory levels, technician productivity, and repair turnaround times, managers can optimize resource allocation and ensure timely repairs without unnecessary delays or overspending.

Enhanced Safety and Compliance

- Ensuring the safety and compliance of fleet vehicles is a top priority for fleet managers.

- Tracking KPIs related to vehicle inspection results, driver compliance with maintenance protocols, and regulatory compliance can help identify potential safety risks and ensure that all vehicles meet legal requirements.

Cost Efficiency and Performance Optimization

- Monitoring KPIs such as maintenance costs per mile, fuel efficiency, and overall fleet uptime can help managers assess the cost-effectiveness and performance of their fleet maintenance program.

- By analyzing these metrics, managers can identify areas for improvement, implement strategies to reduce costs, and enhance the overall efficiency and reliability of their fleet operations.

Essential Fleet Maintenance KPIs to Track

Tracking key performance indicators (KPIs) is crucial for effective fleet maintenance management. By prioritizing specific KPIs related to vehicle downtime, maintenance costs, and fuel consumption, managers can make informed decisions to optimize fleet operations.

Vehicle Downtime

Monitoring vehicle downtime is essential to ensure fleet efficiency and productivity. By tracking the following KPIs, managers can identify patterns and take proactive measures to minimize downtime:

- Mean Time Between Failures (MTBF)

- Mean Time to Repair (MTTR)

- Percentage of Unplanned Downtime

Maintenance Costs

Controlling maintenance costs is key to maximizing fleet profitability. By focusing on the following KPIs, managers can optimize maintenance processes and allocate resources effectively:

- Total Maintenance Costs per Mile/Kilometer

- Preventive Maintenance Compliance Rate

- Cost of Parts and Labor per Work Order

Fuel Consumption

Managing fuel consumption is critical for reducing operational costs and environmental impact. By tracking the following KPIs, managers can identify areas for improvement and implement fuel-saving strategies:

- Average Fuel Efficiency

- Fuel Consumption per Distance Traveled

- Idle Time Percentage

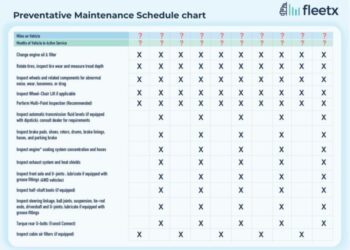

Preventive Maintenance Compliance and Asset Utilization

Ensuring preventive maintenance compliance and maximizing asset utilization are key to enhancing fleet performance and longevity. By monitoring these KPIs, managers can improve overall fleet operations:

- Percentage of Vehicles on Schedule for Preventive Maintenance

- Asset Utilization Rate

- Percentage of Vehicles Available for Use

Setting Targets and Benchmarks for KPIs

Setting realistic targets and benchmarks for Key Performance Indicators (KPIs) is crucial for the effective management of fleet maintenance. By establishing achievable goals and comparing performance against industry standards or previous results, managers can track progress and make informed decisions.

Here are some insights on how to set targets and benchmarks for KPIs:

Establishing Realistic Targets

- Define specific, measurable, attainable, relevant, and time-bound (SMART) goals for each KPI to ensure clarity and focus.

- Consider historical data and trends to set realistic targets that challenge the team without being unattainable.

- Involve key stakeholders in the goal-setting process to gather input and align objectives with the overall business strategy.

Importance of Benchmarking

Benchmarking KPIs against industry standards or past performance provides valuable context for evaluating success and identifying areas for improvement. It allows managers to:

- Gain insights into how the fleet maintenance performance compares to competitors or best practices in the industry.

- Track progress over time and measure the effectiveness of implemented strategies or initiatives.

- Identify outliers or areas of underperformance that require attention and corrective actions.

Adjusting Targets Based on Business Needs

- Regularly review and reassess targets based on changing business needs, market conditions, or technological advancements.

- Be flexible in adjusting targets to accommodate unforeseen challenges or opportunities that may impact fleet maintenance operations.

- Utilize real-time data and feedback to make informed decisions about revising targets to ensure alignment with organizational goals.

Utilizing Technology for Monitoring KPIs

Technology plays a crucial role in tracking fleet maintenance KPIs efficiently and effectively. By utilizing various software and tools, managers can streamline data collection, analysis, and reporting for better decision-making.

Telematics

Telematics systems integrate GPS technology with onboard diagnostics to provide real-time monitoring of vehicle health and performance. This allows managers to track KPIs such as fuel efficiency, engine health, and maintenance schedules accurately.

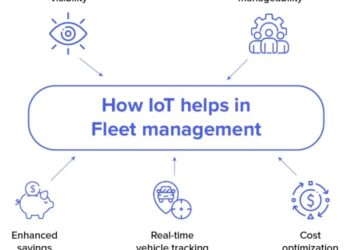

IoT (Internet of Things)

IoT devices can be installed in vehicles to gather data on various parameters like temperature, pressure, and vibration. By analyzing this data in real-time, managers can proactively address maintenance issues, reducing downtime and improving fleet efficiency.

Fleet Management Systems

Fleet management systems offer a comprehensive solution for monitoring fleet maintenance KPIs. These systems can automate maintenance scheduling, track vehicle utilization, and generate detailed reports for performance analysis. By leveraging such systems, managers can optimize maintenance workflows and enhance overall fleet productivity.

Ending Remarks

In conclusion, Fleet Maintenance KPIs play a pivotal role in enhancing the performance and sustainability of fleet operations. By setting targets, utilizing technology, and focusing on key indicators, managers can steer their fleets towards greater success and longevity. This comprehensive guide serves as a roadmap for managers seeking to elevate their fleet maintenance strategies through effective KPI tracking.

Question Bank

What are some common Fleet Maintenance KPIs that managers should track?

Managers should prioritize KPIs related to vehicle downtime, maintenance costs, fuel consumption, preventive maintenance compliance, and asset utilization to ensure optimal fleet performance.

How can benchmarking KPIs against industry standards benefit fleet maintenance operations?

Benchmarking KPIs helps managers gauge their performance against industry norms, identify areas for improvement, and set realistic targets for continuous enhancement.

What role does technology play in monitoring Fleet Maintenance KPIs?

Technology such as telematics, IoT, and fleet management systems enables real-time tracking of KPIs, streamlining data collection, analysis, and reporting for informed decision-making.

data-ad-client="ca-pub-1784768207398293" data-ad-slot="7141627725" data-ad-format="auto" data-full-width-responsive="true">Fleet Maintenance KPIs Every Manager Should Track sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with casual formal language style and brimming with originality from the outset.

Exploring the importance of tracking KPIs in fleet maintenance is not only essential but also a strategic move for managers looking to optimize their operations. By delving into the world of essential Fleet Maintenance KPIs, this discussion aims to shed light on the crucial metrics that can drive efficiency and cost-effectiveness in fleet management.

Importance of Fleet Maintenance KPIs

Monitoring Key Performance Indicators (KPIs) in fleet maintenance is crucial for ensuring the smooth operation and longevity of a company's vehicles. By tracking specific metrics, managers can gain valuable insights into the health of their fleet and make informed decisions to optimize maintenance processes and reduce costs.

Enhanced Maintenance Planning

- Tracking KPIs such as vehicle downtime, maintenance costs, and preventive maintenance compliance allows managers to identify patterns and trends in maintenance needs.

- With this data, managers can create comprehensive maintenance schedules, anticipate potential issues, and proactively address maintenance requirements, minimizing unexpected breakdowns and disruptions.

Improved Resource Utilization

- Efficiently managing resources like labor, parts, and equipment is essential for maintaining a cost-effective fleet maintenance program.

- By monitoring KPIs related to inventory levels, technician productivity, and repair turnaround times, managers can optimize resource allocation and ensure timely repairs without unnecessary delays or overspending.

Enhanced Safety and Compliance

- Ensuring the safety and compliance of fleet vehicles is a top priority for fleet managers.

- Tracking KPIs related to vehicle inspection results, driver compliance with maintenance protocols, and regulatory compliance can help identify potential safety risks and ensure that all vehicles meet legal requirements.

Cost Efficiency and Performance Optimization

- Monitoring KPIs such as maintenance costs per mile, fuel efficiency, and overall fleet uptime can help managers assess the cost-effectiveness and performance of their fleet maintenance program.

- By analyzing these metrics, managers can identify areas for improvement, implement strategies to reduce costs, and enhance the overall efficiency and reliability of their fleet operations.

Essential Fleet Maintenance KPIs to Track

Tracking key performance indicators (KPIs) is crucial for effective fleet maintenance management. By prioritizing specific KPIs related to vehicle downtime, maintenance costs, and fuel consumption, managers can make informed decisions to optimize fleet operations.

Vehicle Downtime

Monitoring vehicle downtime is essential to ensure fleet efficiency and productivity. By tracking the following KPIs, managers can identify patterns and take proactive measures to minimize downtime:

- Mean Time Between Failures (MTBF)

- Mean Time to Repair (MTTR)

- Percentage of Unplanned Downtime

Maintenance Costs

Controlling maintenance costs is key to maximizing fleet profitability. By focusing on the following KPIs, managers can optimize maintenance processes and allocate resources effectively:

- Total Maintenance Costs per Mile/Kilometer

- Preventive Maintenance Compliance Rate

- Cost of Parts and Labor per Work Order

Fuel Consumption

Managing fuel consumption is critical for reducing operational costs and environmental impact. By tracking the following KPIs, managers can identify areas for improvement and implement fuel-saving strategies:

- Average Fuel Efficiency

- Fuel Consumption per Distance Traveled

- Idle Time Percentage

Preventive Maintenance Compliance and Asset Utilization

Ensuring preventive maintenance compliance and maximizing asset utilization are key to enhancing fleet performance and longevity. By monitoring these KPIs, managers can improve overall fleet operations:

- Percentage of Vehicles on Schedule for Preventive Maintenance

- Asset Utilization Rate

- Percentage of Vehicles Available for Use

Setting Targets and Benchmarks for KPIs

Setting realistic targets and benchmarks for Key Performance Indicators (KPIs) is crucial for the effective management of fleet maintenance. By establishing achievable goals and comparing performance against industry standards or previous results, managers can track progress and make informed decisions.

Here are some insights on how to set targets and benchmarks for KPIs:

Establishing Realistic Targets

- Define specific, measurable, attainable, relevant, and time-bound (SMART) goals for each KPI to ensure clarity and focus.

- Consider historical data and trends to set realistic targets that challenge the team without being unattainable.

- Involve key stakeholders in the goal-setting process to gather input and align objectives with the overall business strategy.

Importance of Benchmarking

Benchmarking KPIs against industry standards or past performance provides valuable context for evaluating success and identifying areas for improvement. It allows managers to:

- Gain insights into how the fleet maintenance performance compares to competitors or best practices in the industry.

- Track progress over time and measure the effectiveness of implemented strategies or initiatives.

- Identify outliers or areas of underperformance that require attention and corrective actions.

Adjusting Targets Based on Business Needs

- Regularly review and reassess targets based on changing business needs, market conditions, or technological advancements.

- Be flexible in adjusting targets to accommodate unforeseen challenges or opportunities that may impact fleet maintenance operations.

- Utilize real-time data and feedback to make informed decisions about revising targets to ensure alignment with organizational goals.

Utilizing Technology for Monitoring KPIs

Technology plays a crucial role in tracking fleet maintenance KPIs efficiently and effectively. By utilizing various software and tools, managers can streamline data collection, analysis, and reporting for better decision-making.

Telematics

Telematics systems integrate GPS technology with onboard diagnostics to provide real-time monitoring of vehicle health and performance. This allows managers to track KPIs such as fuel efficiency, engine health, and maintenance schedules accurately.

IoT (Internet of Things)

IoT devices can be installed in vehicles to gather data on various parameters like temperature, pressure, and vibration. By analyzing this data in real-time, managers can proactively address maintenance issues, reducing downtime and improving fleet efficiency.

Fleet Management Systems

Fleet management systems offer a comprehensive solution for monitoring fleet maintenance KPIs. These systems can automate maintenance scheduling, track vehicle utilization, and generate detailed reports for performance analysis. By leveraging such systems, managers can optimize maintenance workflows and enhance overall fleet productivity.

Ending Remarks

In conclusion, Fleet Maintenance KPIs play a pivotal role in enhancing the performance and sustainability of fleet operations. By setting targets, utilizing technology, and focusing on key indicators, managers can steer their fleets towards greater success and longevity. This comprehensive guide serves as a roadmap for managers seeking to elevate their fleet maintenance strategies through effective KPI tracking.

Question Bank

What are some common Fleet Maintenance KPIs that managers should track?

Managers should prioritize KPIs related to vehicle downtime, maintenance costs, fuel consumption, preventive maintenance compliance, and asset utilization to ensure optimal fleet performance.

How can benchmarking KPIs against industry standards benefit fleet maintenance operations?

Benchmarking KPIs helps managers gauge their performance against industry norms, identify areas for improvement, and set realistic targets for continuous enhancement.

What role does technology play in monitoring Fleet Maintenance KPIs?

Technology such as telematics, IoT, and fleet management systems enables real-time tracking of KPIs, streamlining data collection, analysis, and reporting for informed decision-making.

data-ad-client="ca-pub-1784768207398293" data-ad-slot="7141627725" data-ad-format="auto" data-full-width-responsive="true">